The Hidden Cost of Doing It the ‘Old Way’

Imagine this: Your sales team receives a request for a quote. They scramble to gather drawings, email engineers for estimates, input numbers into spreadsheets, and finally—after hours or even days—return with a quote for the customer. Sound familiar? This ‘standard’ quoting process is painfully slow and riddled with inaccuracies. If you’re using Excel sheets that haven’t been updated in months or relying on someone’s memory for machine runtimes, you’re playing a dangerous game of precision roulette. Every manual entry is a potential error. Even a tiny miscalculation in material usage or machine time can erode your margins or, worse, result in customer conflicts. Meanwhile, your competitors might respond in hours, not days. Customers don’t just expect speed—they demand it. In quoting, the slowest bidder loses. So every time you drag out the quoting process, you hand your prospects to a faster, more agile competitor. This lag isn’t just frustrating—it’s bleeding your business. So why are you still doing things the hard way?

The Time Drain You Can’t See… Until It’s Too Late

Let’s talk numbers. The average mid-sized manufacturing business spends anywhere from 3 to 8 hours crafting a single quote when done manually. Multiply that by the dozens of requests coming in every month, and you’re looking at hundreds of hours wasted yearly—time that could be spent optimizing production lines, securing new partnerships, or improving customer experience. What’s worse is that manual quoting stalls decision-making and paralyzes your sales pipeline. Prospects waiting days for a quote often move on. Your team, bogged down by repetitive tasks, loses morale and momentum. And your cash flow suffers. Decision-makers typically underestimate the true opportunity cost of manual quoting because it doesn’t show up on balance sheets—but it shows up in lost deals, late responses, and stagnating growth. It’s not a workflow issue; it’s a revenue leak. And it’s one that often goes unnoticed until the quarterly numbers disappoint. So how can you plug this invisible drain on your productivity and profitability?

The Automation Advantage: From Days to Minutes

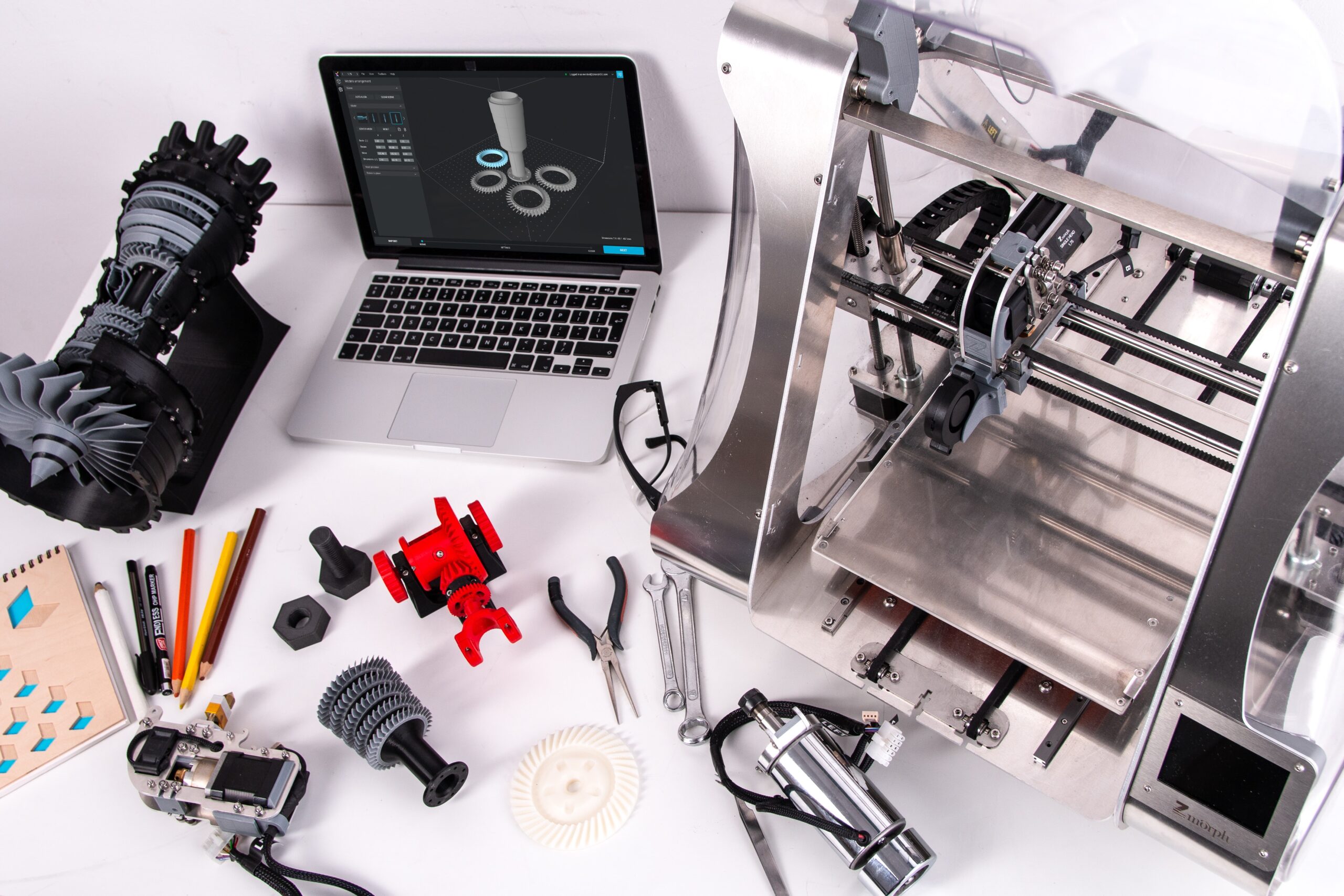

Enter QuotationX, the software tool changing the way manufacturing companies—especially those in 3D printing—handle quoting. Instead of spending hours on back-and-forths, data entry, and manual calculations, QuotationX automates the entire quoting process. Simply input your design parameters, and in minutes you receive an accurate, professional quote that factors in labor, machine time, material costs and markups. The result? A 75% reduction in quoting time. That means what used to take 4 hours can now take under 1. And this isn’t a case of speed over accuracy. Because QuotationX uses real-time data and cost intelligence, your quotes are not only faster—they’re smarter. This means higher profit margins (up to 30% more, according to industry users) and fewer pricing errors. With customer response time slashed from days to minutes, you close deals faster and look more professional in the process. Isn’t it time your quoting process caught up to your production capacity?

Data-Driven Decisions That Boost Your Bottom Line

Quoting isn’t just about prices—it’s about strategy. With QuotationX, every quote you generate adds to a growing pool of data that reveals what’s working, what’s not, and where your profits lie. Want to know which projects bring in the most margin? Or which clients consistently demand more resources than they pay for? The platform offers built-in analytics that help you make smarter business calls—on pricing, scheduling, and customer value. No more flying blind. Even better: these insights aren’t hidden behind spreadsheets or expert-only dashboards. They’re visual, actionable, and designed for real-world manufacturing workflows. This isn’t just quoting software—it’s a decision-making engine that integrates seamlessly with your operations. Imagine having the clarity to adjust pricing strategies, forecast material needs, and plan staffing based on real-time data, not gut instincts. That’s not a future fantasy—it’s happening now for teams using QuotationX.

From Quoting Chaos to Operational Clarity

Now picture this: your sales team gets a request. In 15 minutes, they respond with a precise, visually polished quote. Your client is impressed, and the deal moves forward—no delays, no backtracking. Meanwhile, you’re spending more time scaling production and less time cleaning up quoting messes. That’s the transformation QuotationX delivers. And the best part? It doesn’t require expensive overhauls or months of onboarding. It’s plug-and-play for smart manufacturers who are done losing time and money on antiquated processes. Manual quoting is no longer just inefficient—it’s a liability. Those who automate have the edge, and that edge is only widening. If you’re still stuck in the old way of doing things, your competitors are already two steps ahead. But the good news is, it’s not too late to catch up—and even leap ahead. Make your quoting process a growth catalyst, not a bottleneck. Ready to finally quote with confidence? Click now to see how QuotationX can change everything.